Advanced Machinery

State-of-the-Art Printing, Forming, and Packaging Machines for High-Quality and Efficient Solutions.

Precision engineering for flawless packaging production.

Reliable performance for uninterrupted production.

User-friendly design for easy operation and maintenance

Eco-friendly with low energy consumption

Flexographic Printing Machine.

Economical & eco-friendly printer for cup paper. Prints 4-6 color specs & sizes, using water-soluble ink & automatic correction.

Economical and eco-friendly printing for cup paper.

Suitable for single/double side PE coating paper.

Automatic correction and corona equipment for great printing.

Customizable for 4-6 color specifications.

Soup Bowl Forming Machine.

High-speed single-rotary paper bowl machine with integrated working station. Fast, stable, and automated with precise control.

- Speed: 60-80 bowls/min

Lubrication: Automatic spray oil system

Transmission: Helical gear system for stability and longevity

Features: LEISTER bottom heaters, EVER GREEN ultrasonic side welder, Delta control system

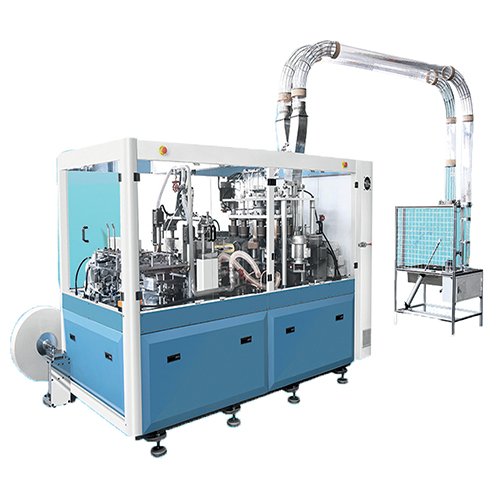

High Speed Paper cup Forming Machine.

Fully automatic machine for producing various sizes of paper cups with efficiency and precision.

Hot air bottom sealing, ultrasonic cup side sealing.

High-performance machine with separate turn-plates for top curling and bottom knurling.

Easily change molds to create cups of different sizes.

Equipped with automatic cup delivery system and counter.

Double Wall Cup Forming Machine.

Upgrade your coffee and tea cup production with the LS-DW001 double wall cup forming machine. Automatic lubrication and open cam mechanism ensure smooth operation. Make double wall and ripple cups on the same machine.

Smooth and efficient operation for high productivity

Make double wall and ripple cups on the same machine

Automatic lubrication to ensure minimal maintenance

Ideal for coffee and tea cup production

Paper cup forming machine

Paper cup forming machine

LS-M001 is an upgraded and efficient machine that uses three turnplates to complete the entire paper cup forming process. It features precise control, high-speed operation, and automatic shutdown in case of malfunctions.

High-speed and efficient production for productivity boost.

Precise and uniform cup size for consistent quality.

Advanced technology and design for optimal performance.

Automatic malfunction detection and CCD image system for defect-free cups.

Paper Slitting Machine.

LS-SC001 is designed for precise slitting and trimming of large coiled materials such as plastic films, paper, and laminated materials used in printing and packaging.

Round blade slitting for high precision and easy operation. Adjustable slitting blades

Independent A/B shaft rewinding for easy installation and operation.

Air-expansion shafts for rewinding and unwinding with automatic tension control for neat rewinding.

Pneumatic pressure lift for automatic feeding support. Automatic discharging of discarded side

Box Forming Machine.

LS-PBW001, a versatile carton erecting machine, is designed to produce various types of containers such as burger boxes, food pail boxes, French fries boxes, and more, using cardboard paper and corrugated paper.

- Able to produce different products on one machine.

Short time required to change the mould.

- Controlled by PLC system, able to produce complicated boxes.

Finished products are collected, stacked and counted automatically.

Die Cutting Machine.

Efficiently Die Cut, Crease, Emboss & Strip Various Coated and Plastic Materials with Precision.

High speed of 90-140 times per minute for efficient production.

Precise paper positioning with photoelectric sensor

Safe & user-friendly with PLC and HMI control system

Powerful pressure and convenient operation with pneumatic locking system.

Paper Plate Forming Machine.

LS-MPlate is a high-performance machine designed for efficient production of paper plates. Its features include:

Fast oil pressure system: Each station operates 15-20 minutes faster than ordinary machines, thanks to independent research and development.

Mechanical paper feeding: Ensures stable performance and significantly reduces waste rate (1/1000) compared to traditional paper drop technology.

- Hydraulic oil recycling: Reduces emission pollution and minimizes noise levels.

Compatibility with packaging machines: Can be seamlessly integrated with packaging and labeling systems for efficient packaging of paper plates.

Paper Cup Packing Machine.

CP-650 machine is easy to operate(a person), stable performance, high efficiency, it introduces the advanced technology completely

Max. Packaging speed 20bags/minute

- packaging film materials HDPE,LDPE

Max. Unwinding diameter 300mm

packaging film thickness 15um-30um

Automatic Plastic Lid/Cover Machine

Advanced PC-controlled cutting machine with high automation function.

Integrated electricity & optics technology for efficient cutting.

Temperature-controlled material molding for precise cuts.

User-friendly PLC computer control for ease of use.

High automation function for increased productivity.

Automatic paper lid/cover machine.

PL-145 is a high-performance machine designed for the production of paper soup bowl covers, coffee cup lids, and paper container lids. Its features include:

Cost-saving lid production: The machine uses one disc paper to create lids, saving on raw material costs.

Secure lid design: The paper lid is folded on the side and gently locks onto the cup, effectively preventing water leakage.

Easy operation and stable performance: The machine can be operated by a single person and offers reliable and consistent performance.

- High efficiency and energy-saving: The machine incorporates advanced technology to optimize efficiency, save energy, and reduce raw material consumption.

Contacts Us!

Location

China factory:

No.1-99 Haixi Road, Longgang Town , Cangnan Country, Wenzhou City , zhejiang province , China.

Egypt Office:

5 Ahmed Fahim st, Al Hay al Sabea, Nasr City, Cairo.

Phone

China factory: 0577-6858-8209

Egypt office: +20 (2) 2384-6677

Contact

Open Hours

Sat– Thur . 8:00 – 17:00